The Union Carbide Mining Machine

|

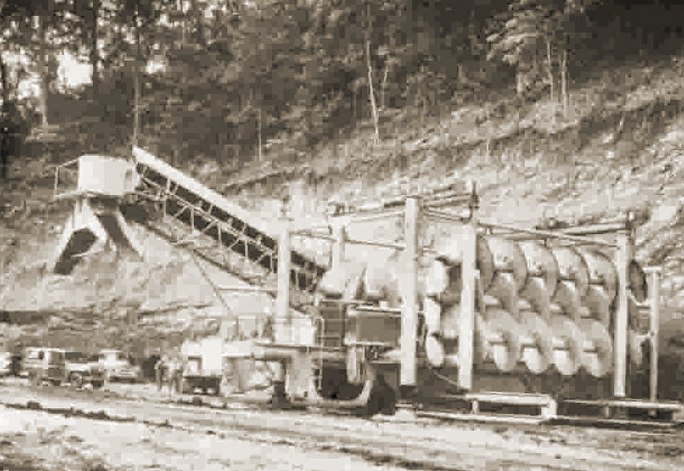

Carbide invented a remote control

coal mining machine in South Charleston WV at the Tech Center that

changed mining forever. The machines were tested and improved at

Sanderson WV. in the 1950s. By 1958, the Patents were sold to Joy

Manufacturing.

|

AND IT BEGINS....

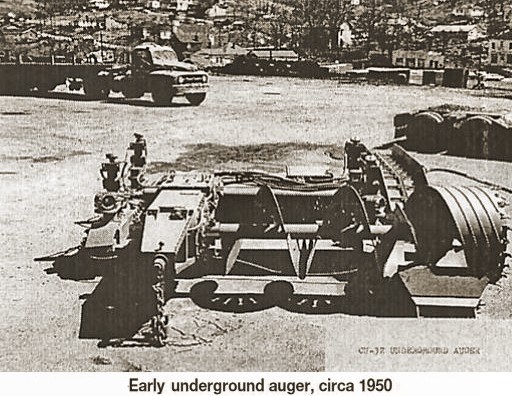

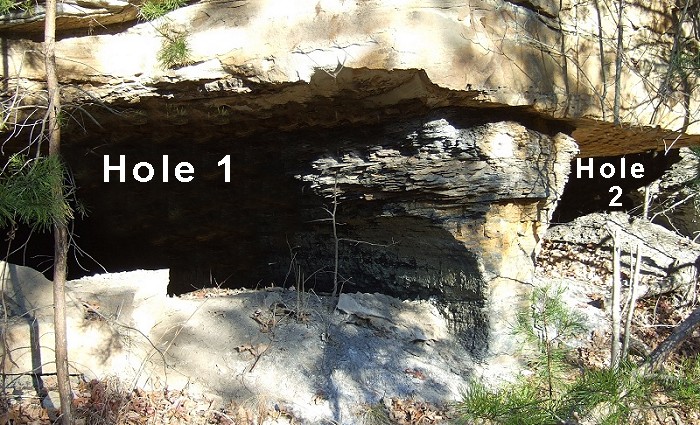

There were two systems used in the Sanderson/Bluecreek

area: The Highwall Auger miner, and the "Mole Miner". You

can easily tell the difference between the two when you vist the

area: The Auger mine has perfectly round holes, while the "Mole

Miner" holes are are more oblong.

A mole miner is a machine that can cut a “blind” narrow

face entry while being remotely-operated. This technology is

composed of several sub-systems: haulage for coal removal,

ventilation, monitoring, and a control and pushing system which

advances the miner into the face. . This method has become more

feasible for thin-seam mining with the development of autonomous mining

machines and has the advantage that personnel do not enter the

extraction zone. The first such miner developed in America was

by the Union Carbide Company to mine coal outcrops exposed in

the highwalls of strip operations, once stripping was no

longer economical. This miner was self-propelled, moving its

haulage system behind it. The cutting height was kept to no more than 5

ft. The miner maintained its position in the seam utilizing pick force

sensing to detect differences in rock hardness.

|

THIS ARTICLE DISCUSSES CARBIDES NEW "MOLE MINER", NOT TO BE CONFUSED WITH AUGER MINING

|

JOY MANUFACTURING BUYS THE CARBIDE PATENTS

|

HIGHWALL AUGER MINING

BACKGROUND

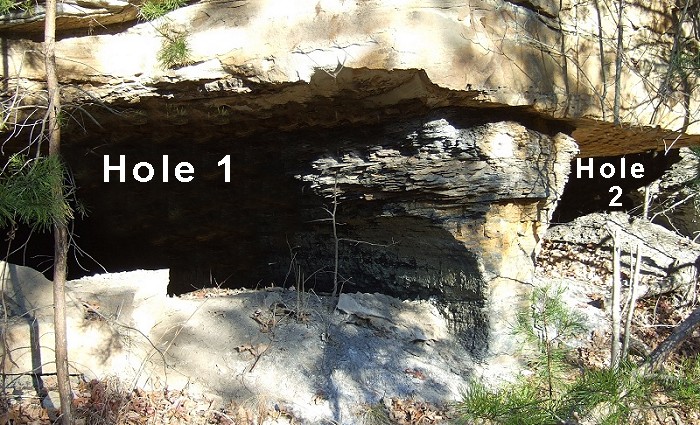

This is the type of hole left behind from Carbide's new "Mole Miner".

As you can see, it's more oblong than round.

There are many hundreds of them in the hills around Sanderson WV.

This shows the distance between each hole, leaving a thin pillar between holes for support.

There is shoring in many of these holes where I believe the natural pillars weren't enough to hole up the roof.

|

POST SCRIPT: I

have been searching for actual photographs of the Carbide "Mole Miner"

Machines and the men that operated them for years to no avail. My

guess is that while the machines were being tested, it was a secret

operation to protect Patents. If you have or know of anyone who

has photos of the Sanderson WV area mining operations, please contact

me. jerry@mywvhome.com

|

© COPYRIGHT

All content

including articles and photos on this website Copyright 2020 by J.

Waters. All images on this website are used with permission or

outright ownership of J. Waters.

All newspaper

articles are courtesy of the Charleston Gazette or Daily Mail for the

express use of the author. You do NOT have permission to use any image,

article or material without permission from the author. You do

NOT have permission to pull photos from this website and post them to

Facebook or any other website. Any material used without

permission will be subject to creative copyright laws.

|

Back to index

|